Our Design / Build Process

Beginning at the initial design and development stages, we collaborate with our clients and their teams to provide continuity and ensure the project’s success. We partner with our clients to offer world-class solutions, from concept to reality. Our comprehensive resources allow us to deliver a level of service that builds lasting partnerships and innovative solutions.

OUR PROCESS

Click numbers below to learn more

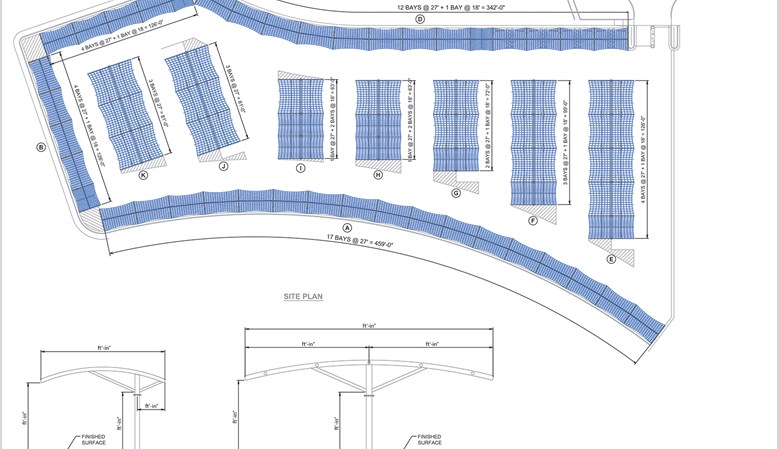

Conceptual Design & Sales Engineering

Our process starts with a comprehensive project feasibility definition. We utilize our vast experience to develop a thorough scope definition that is achieved by devising the most efficient product mix in conjunction with our design and space optimization skills. Our familiarity with regulatory requirements enables us to take the project from initial concept to successful completion in the most efficient and timely manner possible.

Project Design & Engineering

VPS' Design & Engineering Department establishes the required geometry of the structure and then models it in 3D CAD. Design drawings are developed from the 3D model and, along with the Engineering Calculations, submitted to the client for review and approval. Our engineering specifications are designed to meet all local and International Building Code (IBC) requirements.

Project Management

VPS Project Managers are accomplished professionals with years of design/build and construction expertise. Our fast-track process factors in the overlap of design, procurement, fabrication, and construction, while compressing the schedule, significantly reducing costs and maximizing efficiency. Our managers are all well-versed in new construction techniques and in the retrofitting of existing facilities.

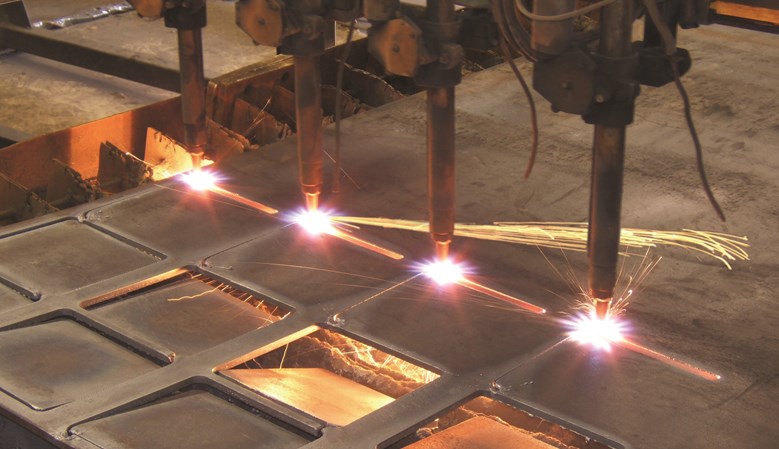

Steel Fabrication

Our team of fabrication professionals consistently produces structures that are among the most durable, cost effective and innovative in the fabric structure industry. VPS has a state-of-the-art steel fabrication facility in Dallas, TX, that is certified by the International Accreditation Services board (IAS) for meeting or exceeding the highest standards in the steel fabrication industry.

Fabric Fabrication

At the core of all our structures are the fabrics that we utilize for optimal hail and weather protection. HDPE, a high density polyethylene mesh, can block out up to 96% of the sun’s harmful UV rays. Other fabrics such as PVC and PTFE can be utilized depending on the specific project requirements as well as our clients’ individual needs and desires.

Construction

VPS' Construction Management team coordinates the installation process using a Means & Methods statement that facilitates operational efficiency through a phased movement of vehicles, while causing minimal disruption to the business. In addition to design, engineering, and permit acquisition, our construction services include surveying, drilling, reinforced pier installation, steel erection, fabric installation, and finishing.

Conceptual Design

Project Design

Project Management

Steel Fabrication

Fabric Fabrication

Construction